Sil-Pads Materials

SIL-PAD CONSTRUCTION

The Construction Behind SIL PAD Performance

Sil-Pads are constructed with a variety of different materials including fiberglass, silicone rubber, polyimide film, polyester film and fillers used to enhance performance. Sil-Pads are typically constructed with an elastomeric binder compounded with a thermally conductive filler coated on a carrier.

The characteristics of your application often determine which Sil-Pad construction will produce the best performance.

Product Overview

Sil-Pad® 2000 is a high-performance thermal interface material designed to eliminate messy thermal greases while providing excellent insulation and heat transfer between power devices and heat sinks.

Its reinforced construction ensures dimensional stability, while its silicone-based design delivers long-term reliability even in high-temperature or high-voltage environments.

This product is ideal for applications requiring:

- consistent thermal performance

- strong electrical isolation

- durable, clean-handling insulation

- long-term stability under mechanical compression

Sil–Pad Benefits

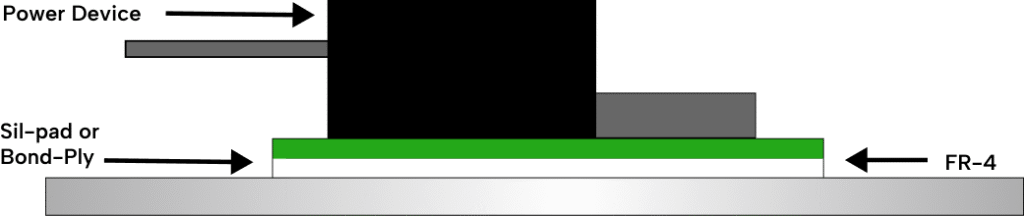

Sil–Pad is the benchmark in thermal interface materials. The Sil Pad family of materials are thermally conductive and electrically insulating. Sil–Pad materials come in a variety of different thicknesses and are frequently used in SMT application such as:

- Interface between thermal via’s in a PCB, and a heat sink or casting

- Heat sink interface to many surface mount packages

Sil–Pad is available in custom shapes, sheets and rolls.

Sil-Pad Selection Guide

Let’s Solve Your Thermal Challenges Together

Get expert support for product selection, datasheets, and engineering guidance tailored to your application needs.