Empowering Innovation Through Smart Thermal and Topical Anti-Static Solutions

ABOUT TJK TECHNOLOGIES

Reliable Thermal & Static-Control Solutions

- 35+ Years of Industry Experience

- Authorized Distributor of Leading Global Brands

- ISO-Certified, High-Quality Product Range

- Reliable Technical Support for Engineers

OUR ACHIEVEMENTS

Delivering dependable solutions backed by experience, expertise, and trust.

OUR PRODUCT CATEGORIES

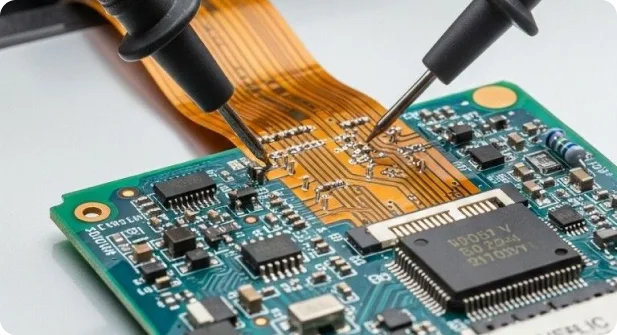

Precision-Engineered Products for

Real World Needs

Reliable substrates for thermal management

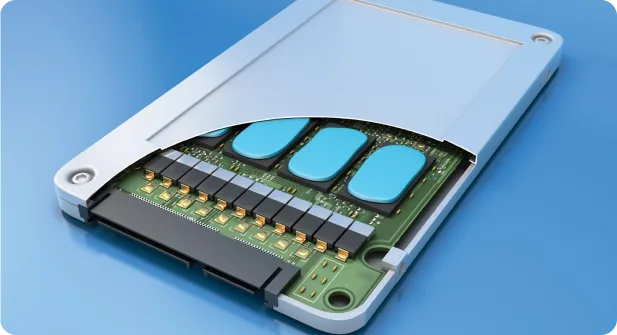

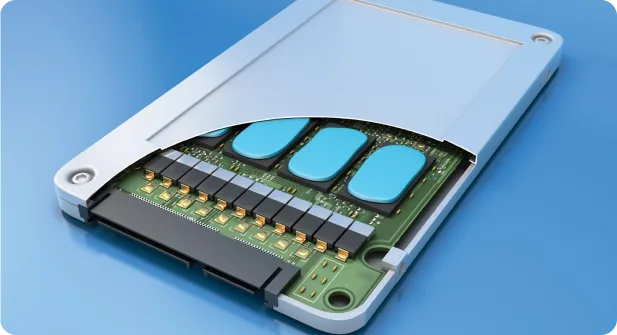

The next generation of electronics brings demanding challenges that require innovative solutions. Thermal Clad meets these needs by making heat transfer an essential part of the design. Its applications span from semiconductor modules and power supplies to motor controls and advanced electronic systems.

Durable, responsive, precision-based touch tech

Experience superior touch performance with Bergquist’s 5-Wire Resistive technology — designed to deliver reliability across a wide range of applications. Available in sizes from 2.4” to 23”, featuring slim perimeters and customizable options to suit nearly any industry need.

Anti-static cleaners and coatings

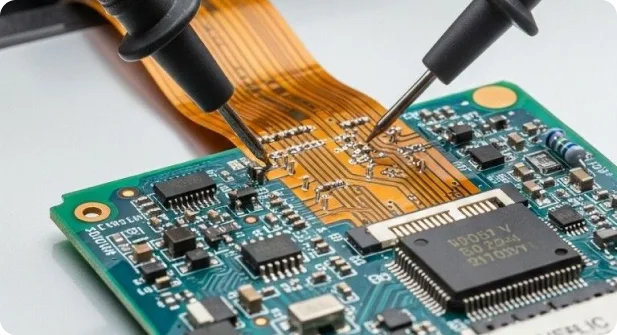

As an authorized distributor of ACL Inc., an ISO 9002 certified company, TJK Technologies delivers cost-effective, timely solutions for all static-related challenges. ACL manufactures and markets static control and computer cleaning products, serving a wide range of industries — from office environments to specialized manufacturing.

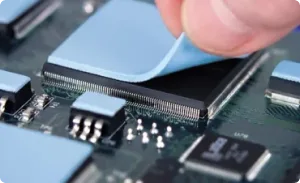

Gap Pads

Soft, conformable materials designed to fill uneven gaps and improve thermal conductivity.

Thermal Interface Materials

High-performance materials for heat transfer

Thermal Clad Substrates

Reliable substrates for thermal management

Industrial Adhesives, Sealants & Surface Technologies

Engineered, high-performance adhesive, sealant and coating solutions

Staticide Solutions

Anti-static cleaners and coatings

CLIENTS REVIEWS

What our client’s say about us

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

Darlene Robet

-Head of R&D, Electronic Developer

Jerome Bell

-Senior Production Engineer

SUPPORT FAQs

Common Questions About Our Products

What is meant by natural tack?

The characteristic of the rubber itself has a natural inherent tack, without the addition of an adhesive. As with adhesive-backed products, the surfaces with natural tack may help in the assembly process to temporarily hold the pad in place while the application is being assembled. Unlike adhesive-backed products, inherent tack does not have a thermal penalty since rubber itself has the tack. Tack strength varies from one Gap Pad product to the next.

Is Gap Pad offered with an adhesive?

Is the adhesive repositionable?

Can Gap Pad with natural tack be repositioned?

Is Gap Pad reworkable?

How is extraction testing performed?

What is the best fastening method for a TIC interface?

How should the TIC be applied?

Will the grease stay in the interface?

Need More Help?

Let’s Solve Your Thermal Challenges Together

Get expert support for product selection, datasheets, and engineering guidance tailored to your application needs.