TIC - Thermal Interface Compounds

Thermal Interface Compounds

Thermally Conductive Grease Compounds

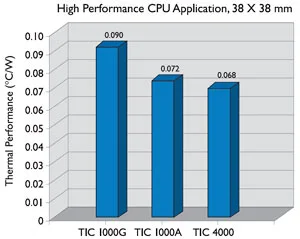

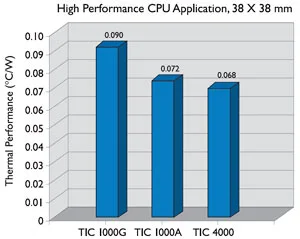

Bergquist’s line of thermally conductive thermal interface compounds will flow under assembly pressure to wet-out the thermal interface surfaces and produce very low thermal impedance. TIC products are designed for use between a high-end computer processor and a heat sink or other high watt density applications.

The TIC portfolio has diversethermal and electrical characteristics. Key criteria when selecting TIC products include:

- Viscosity

- Volume resistivity

- Thermal conductivity

- Thermal performance

- Filler size

TIC products are ideal

for high watt density applications. Primary

benefits include:

- Low interfacial resistance

- Low thermal impedance

- Resists dripping

- Ideally suited to screen printing applications

- No post “cure” conditioning required

TIC products can be obtained with application-specific options such as:

- Containers

Some Gap Pad products have special features for particular applications, including:

- CPU

- GPU

- IGBT

- High power density applications

SUPPORT FAQs

Common Questions About Our Products

What is the best fastening method for a TIC interface?

A: A constant-pressure fastener is preferred when using TIC for high performance applications.The constant pressure from a clip or spring washer will ensure adequate pressure is being applied with varying bond line thickness.

How should the TIC be applied?

Screenprinting the TIC is a fast, low-cost method that delivers a consistent and accurate amount of material on each application.

Alternate methods include stenciling, pin transfer and needle dispensing.

Will the grease stay in the interface?

All the TIC materials were specifically designed to resist pump-out of the interface, even after many hours of thermal and power cycling.

Need More Help?

Let’s Solve Your Thermal Challenges Together

Get expert support for product selection, datasheets, and engineering guidance tailored to your application needs.